Chain Guide Roller

Chain Guide Roller Specification

- IP Rating

- IP65 (Dust and Water Resistant)

- Application Areas

- Industrial Automation, Conveyors, Machinery, Manufacturing Units

- Equipment Type

- Chain Roller Guide

- Usage & Applications

- Conveyor Systems, Material Handling, Chain Transmission Support

- Product Type

- Chain Guide Roller

- Type

- Guide Roller

- Material

- Nylon (Polyamide 66), with Steel Core or Insert

- Drive Type

- Mechanical

- Dimension (L*W*H)

- Diameter: 50150 mm; Width: 2060 mm (custom sizes available)

- Feature

- Abrasion Resistant, High Durability, Low Noise Operation

- Size

- Customisable (Standard: 90 mm x 25 mm Width)

- Surface Finishing

- Smooth Machined Finish

- Power Source

- Not Required

- Features

- Low Friction, Long Service Life, Resistant to Oil, Grease, and Chemicals

Chain Guide Roller Trade Information

- Minimum Order Quantity

- 01 Unit

- FOB Port

- Mumbai

- Payment Terms

- Cheque

- Supply Ability

- Unit

- Delivery Time

- 4 Week

- Main Export Market(s)

- Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Australia, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008 Certified Company

About Chain Guide Roller

Chain Guide Roller

We are manufacturing and supplying a complete range of Chain Guide Roller. Offered range is widely used throughout the world in a variety of applications including drive, tension, shuttle traction and transmission reduction operations. We manufacture entire range by using optimum quality materials sourced from well known vendors of market. These torches are available in a variety of sizes and dimensions to cater the demands of market. Our team checks the quality of entire stock on high industrial norms for ensuring its hassle free performance. Chain Guide Roller is available to our clients at genuine price range.

Features:

- Sturdy construction

- User friendly design

- Easy to operate

Further details:

Chain Guide Roller

- Type: Roller

- Range: Up to 76mm dia chain or as per clients requirement

Superior Durability for Industrial Performance

Featuring advanced abrasion resistance and a steel-reinforced core, the Chain Guide Roller offers unmatched durability and reliability for heavy-duty operation. Its high-grade Polyamide 66 construction enables prolonged use in harsh conditions such as manufacturing units and automated machinery, delivering low friction and extended service life.

Customizable Design for Diverse Applications

Designed to meet various industrial requirements, this guide roller is available in a range of standard and custom dimensions to fit your specific equipment needs. Its smooth machined finish and seamless integration with conveyors or automated systems ensure optimal performance in both small-scale and large-scale setups.

Robust Operation in Challenging Environments

With an IP65 rating, the roller is highly resistant to dust and water intrusion. Its compatibility with oil, grease, and chemicals makes it ideal for demanding applications in material handling and chain transmission. The mechanical drive type also eliminates the need for external power sources, simplifying installation.

FAQs of Chain Guide Roller:

Q: How does the Chain Guide Roller support conveyor systems and material handling applications?

A: The Chain Guide Roller functions as a guiding and support element for chains in conveyor systems and material handling setups. Its low-friction, abrasion-resistant nylon surface ensures smooth chain movement, minimizing wear and providing stable alignment, which is essential for reliable operations in industrial environments.Q: What are the main benefits of using a Polyamide 66 guide roller with a steel core?

A: Combining Polyamide 66 with a steel core provides both strength and resilience. The polymer offers excellent abrasion resistance, low noise, and resistance to oils and chemicals, while the steel core adds structural integrity, extending the rollers lifespan even in demanding mechanical applications.Q: When is it necessary to customize the dimension of the guide roller?

A: Customization is recommended when standard sizes (such as 90 mm x 25 mm width) do not fit your equipment or system specifications. Custom dimensions allow precise integration into specialized machinery, ensuring optimal guidance and longevity for unique conveyor or automation setups.Q: Where can these guide rollers be utilized most effectively?

A: Chain Guide Rollers are best suited for environments like industrial automation systems, conveyors, manufacturing plants, and other machinery-driven units. Their durability and oil/chemical resistance make them adaptable for use in harsh, high-demand industrial settings.Q: What distinguishes this rollers surface finishing and IP rating from typical components?

A: The smooth machined finish of this guide roller results in consistent, low-friction operation and minimal noise, ideal for precision equipment. Its IP65 rating provides robust dust and water resistance, offering reliable performance in environments where contaminants are a concern.Q: Why is no power source required for this chain roller?

A: This guide roller operates mechanically and does not need an external power source. It serves as a passive component, driven by chain or belt movement within the machinery, making installation straightforward and maintenance minimal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Marine Deck Equipment Category

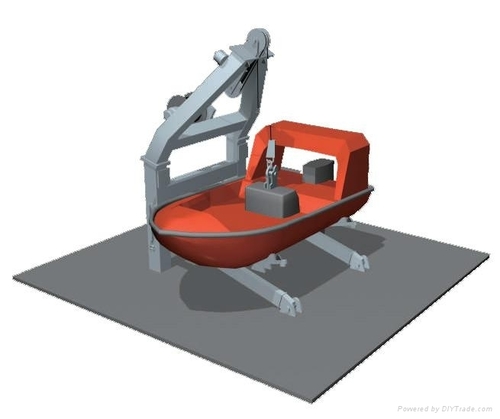

Rescue Boat Davit

Minimum Order Quantity : 1 Unit

Surface Finishing : Marinegrade epoxy paint, hot dip galvanized where specified

Equipment Type : Rescue Boat Davit

Automatic Grade : Other, Optional (manual or fully automatic available)

Usage & Applications : Marine rescue operations, man overboard recovery, lifeboat launching, evacuation procedures

Dimension (L*W*H) : Customized size, typically 3.5 m x 1.2 m x 4.0 m

Single Arm Davit

Minimum Order Quantity : 01 Unit

Surface Finishing : Hotdip galvanized or epoxy painted

Equipment Type : Marine Davit Arm

Automatic Grade : Other, SemiAutomatic / Manual

Usage & Applications : Used to handle davitlaunched lifeboats and rescue boats, especially on marine vessels and offshore platforms.

Dimension (L*W*H) : 2000 mm x 700 mm x 2500 mm (customizable)

A Frame Davit

Minimum Order Quantity : 1 Piece

Surface Finishing : Powder coated or hot dip galvanized

Equipment Type : Portable Davit Crane

Automatic Grade : Other, Manual / Semiautomatic

Usage & Applications : Suitable for lifting, lowering and handling operations in marine, offshore, construction, and industrial sites

Dimension (L*W*H) : Customizable as per requirement (example standard: 2.5m x 1.2m x 3m)

Windlass Anchor Chain Lock

Minimum Order Quantity : 1 Unit

Surface Finishing : Hot dip galvanized

Equipment Type : Deck Equipment

Automatic Grade : Manual

Usage & Applications : Designed to secure anchor chains in marine vessels to prevent accidental deployment or movement.

Dimension (L*W*H) : 300 mm x 140 mm x 80 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS