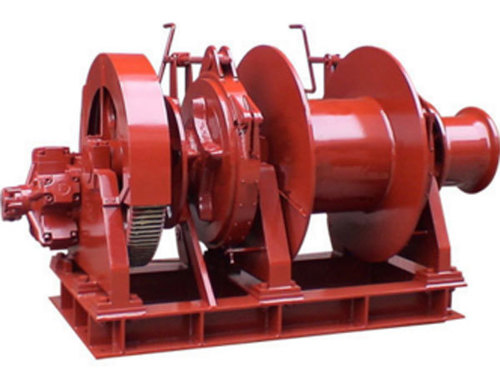

Hydrulic Anchor Mooring Winch

Hydrulic Anchor Mooring Winch Specification

- Power Source

- Hydraulic

- Capacity

- 10-100 Ton

- Speed

- 9-15 m/min

- Drum Capacity

- 50-500 m

- Supporting Load

- As per design

- Wire Rope Diameter

- 18-64 mm

- Working Load

- Variable, as per model

- Rope Type

- Steel Wire Rope

- Number of Drums

- Single or Double

- Brake Type

- Hydraulic/Electric Band Brake

- Power Requirement

- Hydraulic Power Pack, as per system design

- Ambient Temperature Range

- -20°C to +50°C

- Frame Material

- High-strength Steel

- Paint and Corrosion Protection

- Marine Grade Coating

- Mounting

- Deck Mounted

- Operation Mode

- Remote/Manual Control

- Application

- Shipyard, Marine, Offshore Platforms

Hydrulic Anchor Mooring Winch Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque

- Supply Ability

- Unit

- Delivery Time

- 4 Week

- Main Export Market(s)

- South America, Western Europe, Africa, Central America, Eastern Europe, Australia, Middle East, Asia, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008 Certified Company

About Hydrulic Anchor Mooring Winch

Our quality committed firm has attained the topmost position in this field by providing fine grade Hydrulic Anchor Mooring Winch. The offered offered winch is manufactured under the strict guidance of deft professionals by utilizing premium quality components. A mooring winch is operated in a number of ways and fixed in place on the deck of a ship in key positions. The provided Hydrulic Anchor Mooring Winch can be bought by our valued clients.

Features:

- Robust construction

- Rust resistant nature

- Hassle free performance

- Extended durability

Engineered for Harsh Marine Environments

Our winch features a high-strength steel frame and marine-grade coating, offering exceptional resistance to corrosion and wear in the toughest offshore and marine conditions. This guarantees long-lasting service, minimal maintenance, and reliability whether in shipyards or on offshore platforms.

Flexible and Safe Operation

With the ability to operate remotely or manually, our winch provides adaptability suited to a variety of operational scenarios. Hydraulic or electric band brakes ensure secure anchoring, while seamless deck mounting and adjustable control modes promote safety and efficiency during mooring tasks.

Customizable Performance

Choose between single or double drum options, with steel wire ropes of 1864 mm diameter, and select capacities between 10100 tons. The systems design is versatile to support different load requirements, making it ideal for wide-ranging marine and offshore uses.

FAQs of Hydrulic Anchor Mooring Winch:

Q: How does the hydraulic anchor mooring winch operate in marine and offshore applications?

A: This winch is designed to anchor and moor vessels securely. It uses hydraulic power to wind or unwind high-strength steel wire ropes, enabling precise control over anchoring and mooring processes in shipyards, marine vessels, and offshore platforms.Q: What are the benefits of using a marine-grade coating on the winch?

A: Marine-grade coating protects our winch against corrosive seawater, harsh weather, and environmental wear. This prolongs the equipments lifespan, keeps maintenance costs lower, and ensures reliable operation in tough offshore and marine settings.Q: When is it essential to use remote control operation instead of manual control?

A: Remote control operation is preferred for enhanced safety and efficiency, especially when the winch is located in hazardous or hard-to-reach areas, or during operations that require precise and coordinated adjustments from a distance.Q: Where is the hydraulic anchor mooring winch typically installed?

A: This winch is designed for deck-mounted installation on ships, marine structures, or offshore platforms. Its mounting configuration and corrosion-resistant construction ensure dependable performance above deck, regardless of environmental challenges.Q: What is the process for selecting the appropriate winch drum and capacity?

A: Select drum configuration and capacity based on vessel size, rope length needed (50500 meters), wire rope diameter (1864 mm), and the required load (10100 tons). Consulting with our technical team ensures the winch is customized to your operational demands.Q: How does the hydraulic power pack support the winchs operation?

A: The hydraulic power pack supplies regulated hydraulic pressure, enabling efficient and consistent winch movement. It also allows for variable speed control, smooth operation, and suited power delivery tailored to the specific model and application requirements.Q: What are the main advantages of high-strength steel frames in winch construction?

A: High-strength steel frames provide structural integrity, resist deformation under heavy loads, and increase safety during heavy-duty mooring and anchoring operations. This construction extends the winchs service life, even under rigorous marine conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mooring Winch Category

VFD Controls Winch

Minimum Order Quantity : 1 Piece

Working Load : 10 Ton

Capacity : 10 Ton

Supporting Load : Up to 12 Ton

Power Source : Other, Electric Motor Driven

Drum Capacity : 120 m

Electric Mooring Winch

Minimum Order Quantity : 01 Unit

Working Load : 10 Ton

Capacity : 10 Ton

Supporting Load : 12 Ton

Power Source : Electric

Drum Capacity : 100 m

Hydraulic Anchor Mooring Winch

Minimum Order Quantity : 1 Piece

Working Load : Up to 30 T

Capacity : Up to 30 T

Supporting Load : Up to 30 T

Power Source : Hydraulic

Drum Capacity : 500 m

Mooring Winches

Working Load : Up to 100 Tons

Capacity : 5 to 100 Tons

Supporting Load : Up to 150 Tons

Power Source : Other, Electric, Hydraulic or Pneumatic

Drum Capacity : 50 to 500 meters

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS