Combination Windlass Winch

Combination Windlass Winch Specification

- Power Source

- Electric / Manual / Hydraulic

- Capacity

- 1 Ton to 20 Ton

- Speed

- Up to 15 m/min

- Drum Capacity

- Up to 200 meters

- Supporting Load

- Heavy Duty Loads

- Wire Rope Diameter

- 8 mm to 32 mm

- Working Load

- Depends on Model

Combination Windlass Winch Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cheque

- Supply Ability

- Piece

- Delivery Time

- 4 Week

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008 Certified Company

About Combination Windlass Winch

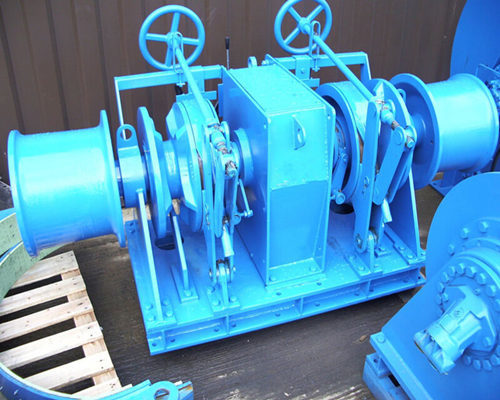

Combination Windlass-winch

We are engaged in manufacturing and supplying a large assortment of Combination Windlass-winch. Offered range is a machine used on ships that is used to let-out and heave-up equipment such as for example a ship's anchor or fishing trawl. We manufacture entire range by using premium quality raw materials sourced from well known vendors of market. Our engineers design these windlass with latest technology following high industrial norms. We offer Combination Windlass-winch to our precious clients at market leading price range in safe packing.

Features:

- Easy to link

- Rust proof

- User friendly design

Further details:

Combination Windlass-winch

Type

- Electric

- Electro-Hydraulic

- Diesel-Hydraulic

Range: Chain size 11.5 mm to 52 mm with / without Rope Drum and wrapping head.

Regulation: As per Classification society rules and requirement.

Engineered for Heavy-Duty Performance

The Combination Windlass Winch is meticulously engineered to tackle the toughest lifting and pulling tasks in marine, dock, construction, and ship environments. Its steel body, enhanced by advanced corrosion-resistant coatings, ensures longevity and reliability even in hostile conditions. With multiple drum types, gear systems, and load capacities, this winch is adaptable to a wide range of demanding operations.

Versatile Controls and Mounting Options

This winch offers flexible control types including remote, pendant, and manual systems, ensuring precise operation tailored to your sites requirements. Base mounting provides stable installation, while finish options such as powder coating or paint protect the equipment from wear and harsh environments. Its designed for seamless integration on ships, docks, or construction sites alike.

FAQs of Combination Windlass Winch:

Q: How is the Combination Windlass Winch typically installed and operated?

A: The winch is base-mounted for stability on ships, docks, or construction sites, and can be operated via remote control, pendant, or manually, offering flexibility according to operational needs and safety protocols.Q: What applications are best suited for this winch model?

A: This winch is ideal for marine, ship, dock, and construction applications where heavy-duty loads up to 20 tons and extended rope lengths up to 200 meters are needed, thanks to its durable steel body and corrosion-resistant finish.Q: When should you select grooved versus ungrooved rope drum types?

A: Grooved drums are recommended when precise rope winding and unwinding is necessary, especially with longer or thicker cables, while ungrooved drums suit applications where frequent re-spooling or varying rope diameters are required.Q: Where can this windlass winch be installed and used safely?

A: It can be securely base-mounted on marine vessels, ship decks, docks, and construction platforms. The robust protection class (IP54/IP55) and corrosion-resistant coatings make it suitable for both indoor and challenging outdoor environments.Q: What is the process for selecting the appropriate model for your needs?

A: Determine the required load capacity (120 tons), drum size, wire rope diameter (832 mm), power source (electric, manual, hydraulic), and speed. Then, match these parameters to your operational and environmental conditions for optimal performance.Q: How does the brake system enhance safety during operation?

A: The winch incorporates both automatic and manual brake systems, providing reliable load control during lifting and lowering, which minimizes the risk of accidental slippage or uncontrolled descent even under heavy loads.Q: What benefits do the advanced insulation and protection classes offer?

A: Class F or H insulation and IP54/55 protection ensure electrical safety, resistance to moisture and dust, and suitable operation in demanding marine and construction environments, enhancing the winchs longevity and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Windlass Winch Category

Helical Gear Box Windlass

Minimum Order Quantity : 1 Piece

Speed : 3 m/min

Drum Capacity : 100 m

Working Load : 10 Ton

Capacity : 10 Ton

Power Source : Electric

Industrial Combination Windlass Winch

Minimum Order Quantity : 1 Unit

Speed : 12 m/min

Drum Capacity : 100 m

Working Load : 10 Ton

Capacity : 10 Ton

Power Source : Electric

Helical Gear Box Windlass Winch

Minimum Order Quantity : 1 Unit

Speed : 10 meters/minute

Drum Capacity : 50 meters

Working Load : 5 Ton

Capacity : 5 Ton

Power Source : Other, Electric motor driven

Electrical Capstan

Minimum Order Quantity : 1 Piece

Speed : 20 m/min

Drum Capacity : 50 m Wire Rope

Working Load : 1 Ton

Capacity : 1 Ton

Power Source : Other, Electric Motor Driven

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS