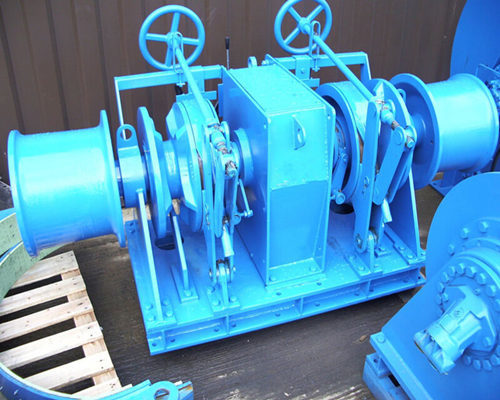

Helical Gear Box Windlass Winch

Helical Gear Box Windlass Winch Specification

- Power Source

- Electric motor driven

- Capacity

- 5 Ton

- Speed

- 10 meters/minute

- Drum Capacity

- 50 meters

- Supporting Load

- 6 Ton

- Wire Rope Diameter

- 16 mm

- Working Load

- 5 Ton

- Finish

- Anti-corrosive Painted

- Gear Type

- Helical Gear Box

- Ambient Temperature Range

- -10°C to +50°C

- Brake System

- Electro-magnetic brake

- Application

- Marine Anchor Windlass, Deck Machinery

- Control System

- Push Button Pendant Control

- Installation

- Base Mounted

- Input Voltage

- 415V AC, 3 Phase

- Duty Cycle

- S4 Intermittent Duty

- Operation

- Electric and Manual (Dual Mode)

- Protection

- IP55 Enclosure

- Frame Material

- Heavy Duty Steel

Helical Gear Box Windlass Winch Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mumbai

- Payment Terms

- Cheque

- Supply Ability

- Unit

- Delivery Time

- 4 Week

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008 Certified Company

About Helical Gear Box Windlass Winch

We have been noted amidst the trustworthy entities, engaged in offering superior Helical Gear Box Windlass Winch. Our valued patrons can easily purchase this winch at economical prices. The provided winch is manufactured by utilizing supreme quality components. To ensure its rust resistant nature, this winch is tested under different parameters. The offered winch is widely demanded in different industries like paper, plastic, oil & gas etc. This Helical Gear Box Windlass Winch is available at reasonable prices for our valued patrons.

Features:

- Smooth operation

- Rugged construction

- Flawless performance

- Extended durability

Robust Design for Demanding Operations

This windlass winch features a heavy-duty steel frame and an anti-corrosive finish, ensuring longevity and resilience against harsh marine conditions. With its dual-mode operationelectric for efficiency and manual for backupyou can confidently rely on the winch in various situations. The IP55 enclosure further elevates its capability to perform reliably in outdoor installations.

Advanced Performance and Control

Equipped with a helical gear box and an electro-magnetic brake, the winch provides smooth torque transfer and dependable stopping. The push button pendant control system allows for easy, safe operation, while the S4 intermittent duty cycle makes it ideal for applications demanding periodic operation without overheating. The base-mounted design simplifies installation and maintenance routines.

FAQs of Helical Gear Box Windlass Winch:

Q: How does the helical gear box improve the performance of the windlass winch?

A: The helical gear box enhances performance by providing smooth and efficient power transmission, reducing noise and vibration while boosting load capacity. Its design minimizes wear, making it ideal for continuous marine operations.Q: What are the advantages of dual (electric and manual) operation in this windlass winch?

A: Dual operation offers versatility and reliability. The electric mode delivers efficiency and ease, while the manual mode ensures continued functionality during power failures or maintenance, providing uninterrupted marine anchoring capability.Q: When should the electro-magnetic brake be engaged during windlass operation?

A: The electro-magnetic brake should be engaged during load holding or when stopping the drum, ensuring secure anchoring or holding position. It is automatically activated via the control system to maximize safety and precise control during operation.Q: Where is this windlass winch typically installed and for which applications?

A: This winch is base-mounted and commonly installed on marine vessels for anchoring, deck machinery, and other related marine applications. Its robust build makes it suitable for industrial and harsh outdoor environments.Q: What is the installation process for the base-mounted windlass winch?

A: The installation involves securing the winch onto a stable base on the vessels deck using appropriate mounting hardware. Electrical connections are made to a 415V AC, 3-phase supply, and the control pendant is routed for operator access. Proper alignment and safety checks should be conducted before commissioning.Q: How does the anti-corrosive finish benefit the windlass winch in marine settings?

A: The anti-corrosive paint finish protects the steel frame from rust and degradation caused by saltwater, humidity, and harsh weather conditions, significantly extending the service life and maintaining reliable performance over time.Q: What makes the windlass winch suitable for intermittent duty cycles?

A: Its S4 duty cycle rating means the winch is designed for periodic operation with breaks, preventing overheating. This makes it ideal for marine and deck applications that require frequent short-duration operation rather than continuous use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Windlass Winch Category

Industrial Combination Windlass Winch

Minimum Order Quantity : 1 Unit

Wire Rope Diameter : 22 mm

Supporting Load : Up to 15 Ton

Power Source : Electric

Speed : 12 m/min

Drum Capacity : 100 m

Helical Gear Box Windlass

Minimum Order Quantity : 1 Piece

Wire Rope Diameter : 18 mm

Supporting Load : 15 Ton

Power Source : Electric

Speed : 3 m/min

Drum Capacity : 100 m

Combination Windlass Winch

Minimum Order Quantity : 1 Piece

Wire Rope Diameter : 8 mm to 32 mm

Supporting Load : Heavy Duty Loads

Power Source : Other, Electric / Manual / Hydraulic

Speed : Up to 15 m/min

Drum Capacity : Up to 200 meters

Electrical Capstan

Minimum Order Quantity : 1 Piece

Wire Rope Diameter : 10 mm

Supporting Load : 1.5 Ton

Power Source : Other, Electric Motor Driven

Speed : 20 m/min

Drum Capacity : 50 m Wire Rope

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS